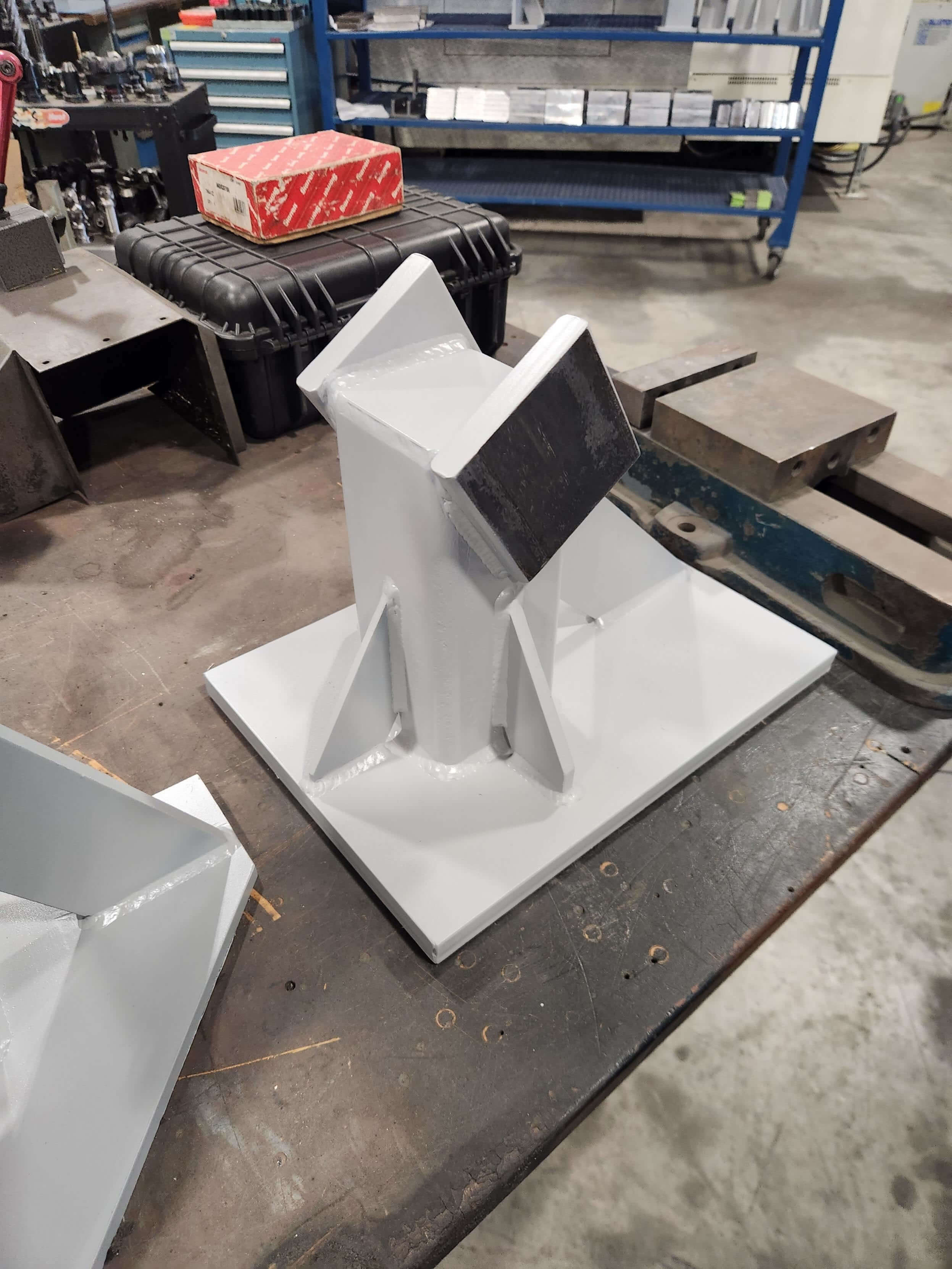

Machining Capabilities

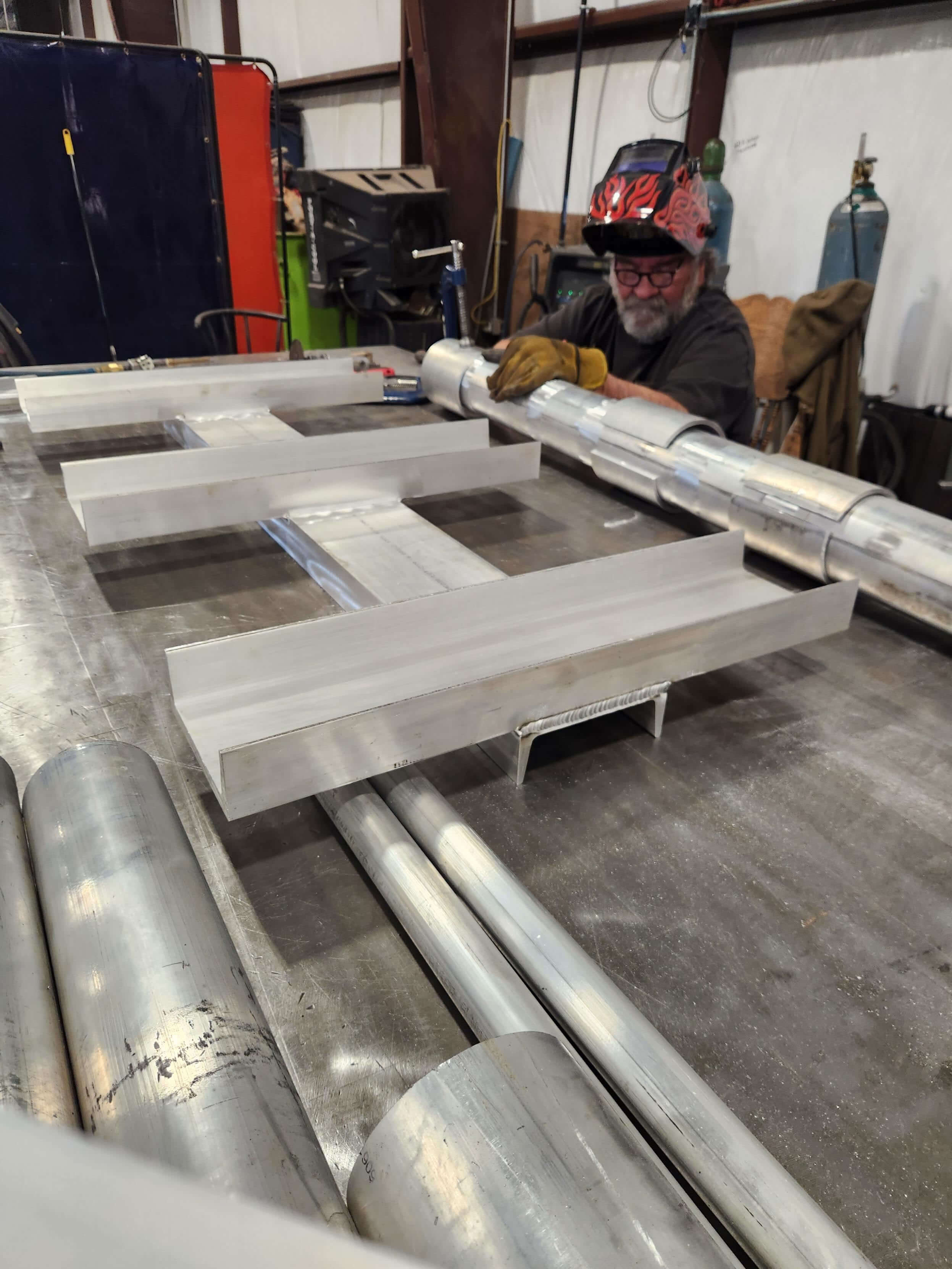

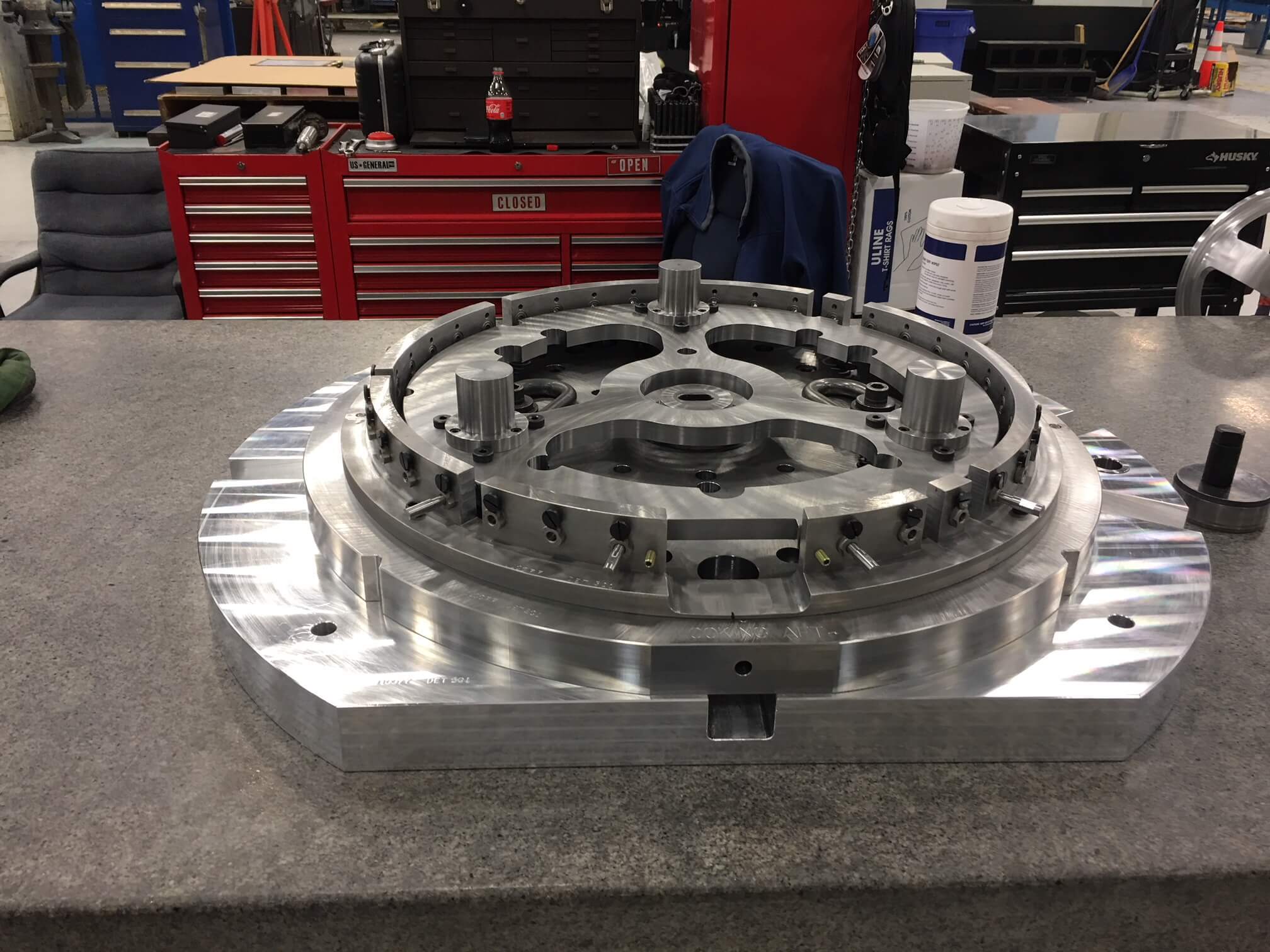

GPT's machine shop is set up for close tolerance, high quality, and quick turn of projects. We are dedicated to providing the detailed precision tooling parts for individual machined part or large assemblies needed in full fixture building.

We have programmers experienced with complex parts programmed in Mastercam and Fusion 360 software.

Our capabilities include both CNC Mill and Lathe capabilities. We have “live tooling” on our CNC lathe.

We have the expertise needed to provide the quality and delivery you need for supporting you project needs.